Description

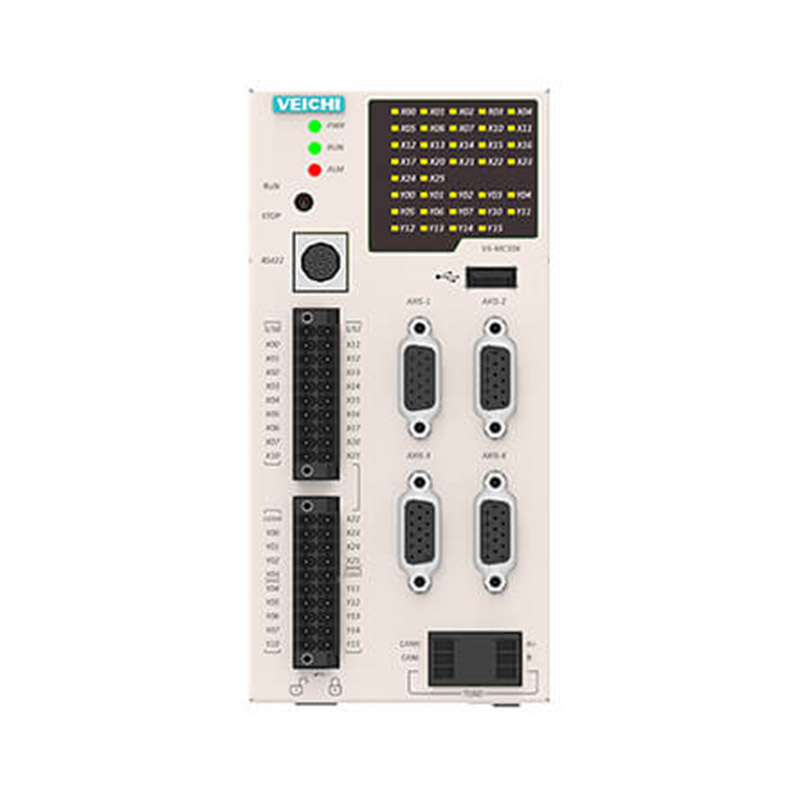

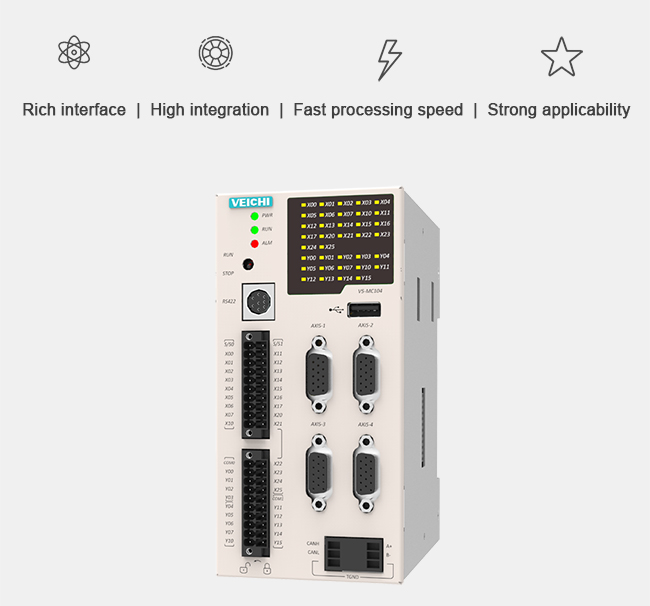

The V5-MC104 series motion programmable logic controller is a multi-axis motion controller developed based on a high-performance processor designed for various industrial automation environments.

1. Support 16-axis synchronous motion, control cycle 125s-1ms.

2. Powerful I/O management and functions meet the logic control requirements of the control system.

3. Modular thinking, convenient function module packaging.

4. Good inheritability, shortening the project development cycle.

5. Users can choose the programming method according to their own habits.

6. Integrate multiple function blocks, just call to apply.

7. Support multiple communication methods.

8. A variety of programming methods, easy to use.

Wide range of applications

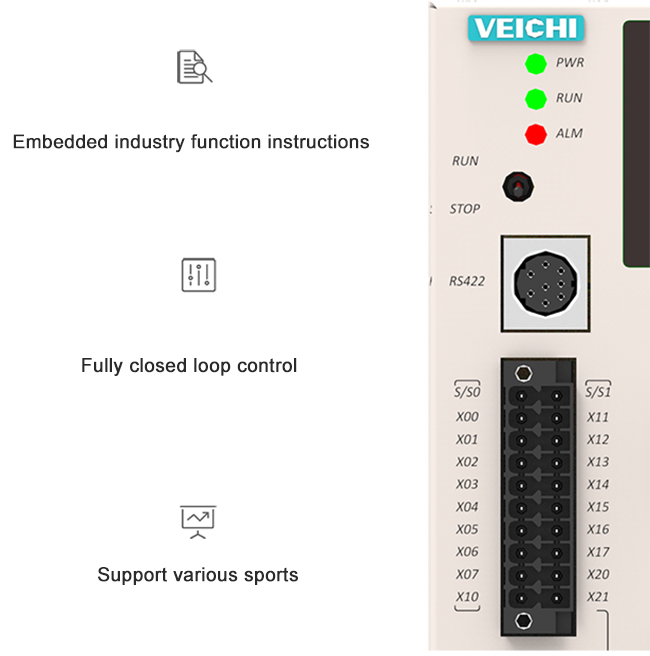

1. Support jog movement, linear interpolation, arc, 3D arc, electronic gear/cam, etc.

2. Built-in a large number of convenient industry function instructions, such as winding, tracking shear, flying shear, packaging, and other industry modules, make the application very simple.

3. Function blocks such as integrated synchronous follow-up, full-closed-loop control, and multi-axis cooperative motion control can be applied simply by calling.

Dual-core main chip, better performance

1. The main chip has dual-core processing and powerful logic operations.

2. The output frequency can be up to 3M.

3. The minimum control period can reach 125s.

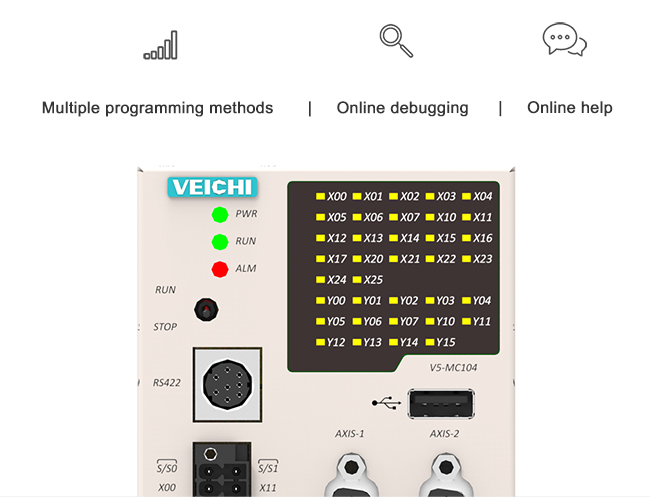

Support online debugging, more convenient operation

1. It supports four programming methods including ladder diagram, instruction list, MC instruction, and G code.

2. Support online debugging and online simulation debugging.

3. Users can quickly find help through the detailed online help function.

Support multiple interfaces, more comprehensive expansion

1. Support multiple communication methods such as RS422, RS485, RS232, CAN, EtherNet, etc.

2. Support USB HOST interface, file copy, and system upgrade.

3. 4-channel AD, 2-channel DA.

4. Expandable input and output interface.

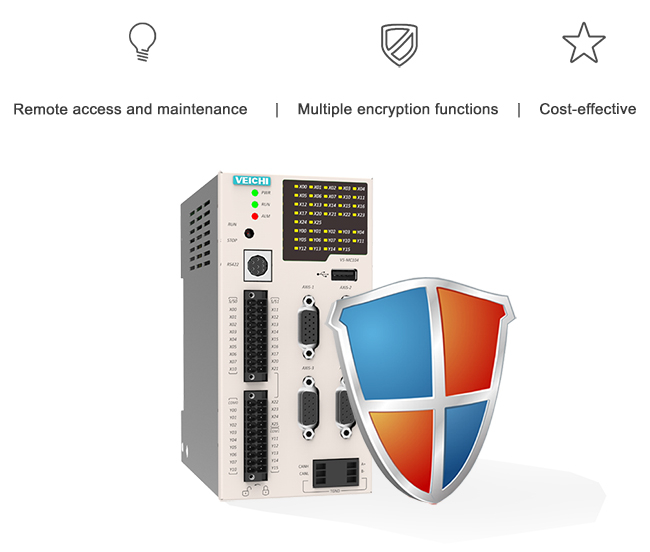

Higher security, more reliable system

1. Support user program encryption, and multiple encryptions.

2. Support user program encryption, and multiple encryptions.

3. Have higher seismic resistance and interference capabilities.

Specification

Software platform: Support ladder diagram, instruction table, sequence function diagram, G code Support remote network access and maintenance Multi-encryption function to ensure user intellectual property rights Support network variables for multi-robot coordination control

Program running mode: Adopt scan mode that can be set to fixed cycle scan, internal event trigger and external event trigger

CPU clock speed: 168M

Memory: 64M

Display interface: RS422, network port